What is a Multi Layer Blow Molding Machine

Whether you notice it or not, plastic products made with multilayer blow molding machines are everywhere. Items may include milk bottles, industrial drums, car gas tanks, sunscreen , lubricating oil ,and other container products.

But how much do you know about the multi layer blow molding machine and everything it can produce? In this blog, we will focus on the principles, types and uses of multi layer blow molding machines.

In this article, we will learn:

What is a multilayer blow molding machine?

Common multilayer blow molding machine type

What is the characteristic of multilayer blow molding machine?

The main application of multilayer blow molding machine

What is a multilayer blow molding machine?

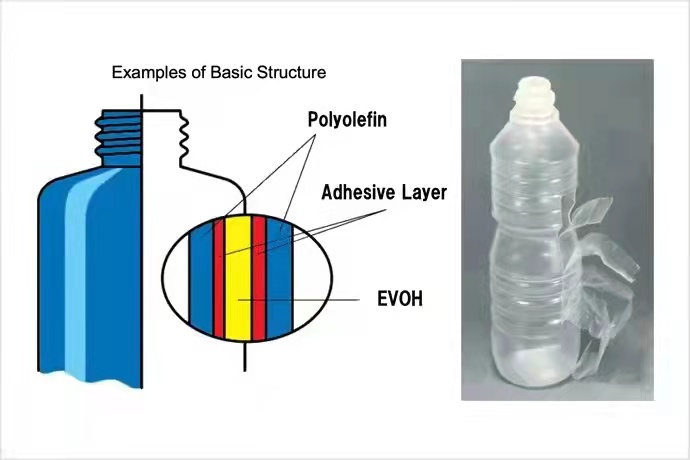

A multi-layer blow molding machine extrudes multiple layers of plastic film and overlays them to form a composite film. Firstly, plastic particles are heated and melted, and then a thin film is formed through an extruder. After cooling and stretching, the thin bottle is rolled to form a multi-layer composite film.

Common multilayer blow molding machine type

1.Two-layer blow molding machine: Consists of two extrusion units and one die head, capable of producing plastic bottle with two layers of different properties. It is commonly used for manufacturing packaging materials with varying moisture resistance and freshness requirements.

2.Three-layer blow molding machine: Comprises three extrusion units and one die head, allowing the production of bottle with three layers of different characteristics. It is suitable for manufacturing functional packaging bottle, such as materials with thermal insulation, barrier properties, and protective features.

3.Multilayer co-extrusion blow molding machine(Four-layer blow molding machine,Five-layer blow molding machine,six-layer blow molding machine): Utilizes a single extrusion unit and a special die head structure to extrude multiple different plastic materials and form a multilayer structure. It is ideal for producing bottle with complex structures and multilayer configurations, including bottle with barrier properties or decorative requirements.

What is the characteristic of multilayer blow molding machine?

Advantages

A multi-layer blow molding machine extends the validity time of filling materials and enhances product selling by creating a barrier against external factors and offering functional benefits, while also potentially reducing competition in the market.

Disadvantages

the disadvantages of multi-layer blow molding machines include their complex equipment, requiring higher technical expertise and maintenance costs. They consume relatively high energy due to the heating, cooling, and extrusion processes involved. Moreover, product design and changes can be challenging, making them less suitable for frequent product switching or the production of specific shapes or sizes of films.

The main application of multilayer blow molding machine.

The main applications of a multi-layer blow molding machine include, but are not limited to, the following industries:

1.Packaging Industry: Multi-layer blow molding machines are used to produce plastic bottle for packaging food, pharmaceuticals, cosmetics, and daily-use products. The multi-layer structure provides excellent freshness preservation, moisture resistance, and barrier properties, extending the shelf life of the products.

2.Agricultural Industry: Multi-layer blow molding machine for the manufacture of pesticide bottles. These bottle help regulate temperature, maintain humidity, resist pests, and provide suitable growing environments, promoting crop growth and yield.

3.Industrial Industry: Multi-layer blow molding machines produce plastic bottle for industrial packaging, protective materials, soundproofing materials, and insulation materials, among others. These bottles exhibit good physical properties and durability to meet the requirements of various industrial applications.

4.Construction Industry: Multi-layer blow molding machines are used to produce construction bottle, such as thermal insulation films and roof waterproofing bottle. These bottle provide insulation, waterproofing, and protection functions, improving the energy efficiency and protective performance of buildings.

5.Medical Industry: Multi-layer blow molding machines are utilized to manufacture plastic bottle for medical packaging, medical devices, medical bags, and surgical drapes, among others. These bottles offer excellent hygiene properties and biocompatibility, ensuring the safety and hygiene of medical equipment and products.

In summary, the main applications of a multi-layer blow molding machine cover a wide range of industries, including packaging, agriculture, industry, construction, and medical sectors, fulfilling the specific functional and performance requirements of plastic bottle in different industries.

Our Products

- Single station blow moulding machine

- Double Station Blow Moulding Machine

- Auto Deflashing Blow Moulding Machine

- Continuous Parison Blow Moulding Machine

- Accumulator Parison Blow Moulding Machine

- Custom Made Blow Moulding Machine

- Toy Making Blow Moulding Machine

- 15 ltr to 60 ltr Blow Moulding Machine

Get in touch

- Plasto Avenue, Plot No - 41, Panchamrut -3 Industrial Park, Village-dhamatvan, Tal.Daskroi, Ahmedabad-382435, GJ(IN)

- +91 6355 731 284

- sales@plastomachine.com

ISO 9001:2015 Certified Company

© Copyrights 2024. All Rights Reserved. Plasto Machine Pvt. Ltd.